July 2012 Newsletter - Thermal Cameras, get a visual on the heat you want to measure!

July 2012 Newsletter - Thermal Cameras, get a visual on the heat you want to measure!

In this month’s newsletter I thought we would dive head first into thermal imaging cameras. We talk about what they are used for and how they work. Tim and Daniel are experts in thermal imaging and are more than happy and capable to answer any questions you have. Remember; if you have any questions regarding tests you need to conduct or specific instrumentation please give us a call. Until next month... |

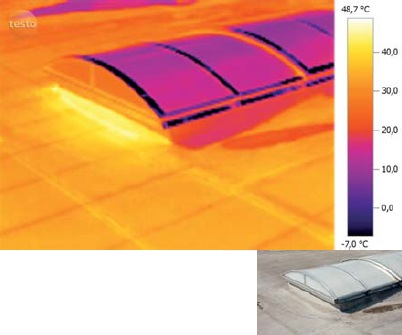

This means that thermal cameras can be used to take images which show how much thermal energy or heat an object is emitting. As thermal cameras can take images of things that would be invisible to the normal eye, they can be used for a wide variety of different applications. These include buildings and pest inspections, preventative maintenance, medical and veterinary checks along with research and development. One popular application is for building inspections. Thermal imaging cameras can be used to find areas that are at a high risk of mould growth, determine areas where insulation is missing, show areas that may be harbouring termites and show heat loss through windows in winter.

Thermal camerascan be used very effectively in situations where infrared thermometers (temperature guns) have had limited success in the past. Infrared thermometers can be easy to use, but, as they only measure one spot at a time, taking measurements can be slow if you have multiple spots or large areas to check. Due to the fact that they take an average reading over a large area, their accuracy is limited and you run the risk of missing small hot spots. An infrared thermometer will allow you to measure one spot at a time, whereas even an entry level thermal imaging camera will allow you to see 3,600 points at a time, capturing all the information you need without missing a thing. | |||

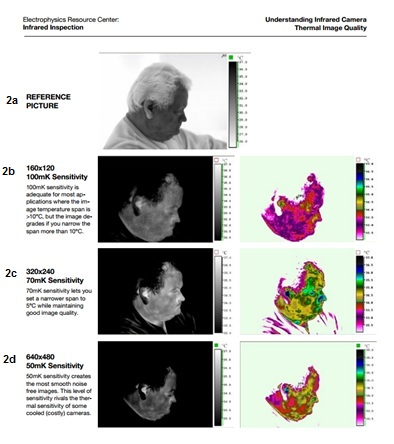

Resolution is directly related to the number of pixels a camera possesses. The higher the number of pixels the higher the resolution and a high resolution results in a clear crisp image. Today there are three common resolution standards however if you are unsure about any of these standards one of customer service officers can point you in the right direction. The three most common resolution standards are: • Low Resolution – ≤ 160x120 (19,600 pixels) How much resolution you need is primarily determined by your application and by the quality of image you desire. Increasing the resolution is the most important consideration in improving image quality. The benefit of a higher resolution camera comes into play when you are looking to zoom into a scene and maintain good image quality. Such as high voltage electrical investigations when you are investigating wiring or transformers. With a low resolution camera the image will appear blurry and won’t provide the information you are looking to obtain. As you will see below with a high resolution camera you can zoom in on an area and still obtain highly accurate and clear images. The second major issue that impacts image quality is thermal sensitivity. Thermal sensitivity basically defines the quality and clarity of the image as you increase image contrast ie. In the images below of a gentlemen’s face, in the first phase of the image 2b there is no real definition between the temperature changes as the thermal sensitivity increases the temperature becomes more defined so there is less blurring of the hot/cold boundaries. This is particularly well demonstrated in image 2d below. The smaller changes in temperature have been detected and displayed allowing for far more accurate temperature profiling.

Another important parameter which can be used to compare thermal cameras is NETD (noise equivalent temperature difference). NETD provides an objective measurement of camera thermal sensitivity where a lower NETD = Less noise and hence a sharper image. This is more apparent in low temperature contrast scenes like the image below. In 2b the image degrades when the span is less than 10°C and the image lacks detail compare this to 2d where the image remains clear even though the temperature differences are small. For those customers looking to enter the market and get a start in thermography you really can’t go past the Flir i3 (call 1300 737 871 for more details). Whilst it may not have the resolution of higher end cameras it is able guide you to areas of electrical issues and is a much more versatile option than an Infrared Thermometer! The Flir range of products are manufactured in Wilsonville, Oregon, and the company also has manufacturing facilities in the USA along with Sweden and France and are of exceptionally high quality. This unit is an essential addition to any maintenance toolbox. If you need a camera that can visualize problems in industrial maintenance and production monitoring before a malfunction or a fire risk occurs the ideal choice is the Testo 875-T1. Whether you are on the trail of energy loss in buildings, helping your customers to save expensive heating costs or ensure site security with its 120 x 160 resolution this camera will provide you with the results you are looking for. The FLIR E60 (call 1300 737 871 for more details) is the top of the line in thermal cameras for identifying electrical, mechanical, or building envelope issues before a failure occurs or an expensive tear-down is required. This camera is best suited to high end applications were high quality results and images are of primary concern. It has a fast reaction time and is highly accurate over a wide temperature range and with its 320 x 240 resolution is ideal for applications where you need to zoom into a scene. | |||