Your Guide To NTC Thermistors

A thermistor is a two terminal resistive transducer which changes its resistive value with changes in surrounding ambient temperature, hence the name thermal-resistor, or simply “thermistor”. NTC thermistors are thermally sensitive resistors whose resistance exhibits a large, precise and predictable decrease as the core temperature of the resistors increases over the operating temperature range. They are primarily used as resistive temperature sensors in probes and current-limiting devices. NTC thermistors are often coupled with other devices such as dataloggers.

What Does “NTC” Mean?

Thermistors are supplied with either a negative temperature coefficient, (NTC) of resistance or a positive temperature coefficient (PTC) of resistance. The difference is that NTC thermistors reduce their resistance as the temperature increases, while PTC thermistors increase their resistance as the temperature increases.

NTC thermistors are the most commonly used (especially the 10KΩ ntc thermistor) and along with an addition series resistor, RS can be used as part of a simple potential divider circuit so that changes to its resistance due to changes in temperature produces a temperature-related output voltage.

Comparing NTC Thermistors to RTD Thermistors (Resistance Temperature Detectors) & Thermocouples

Compared to RTD thermistors/temperature sensors NTC Thermistors are:

- smaller

- faster in terms of response times

- more resistant to shock and vibration

- less expensive;

BUT

- slightly less precise and have a much narrower temperature operating range

- Compared to thermocouples NTC thermistors are:

- have greater sensitivity, stability and accuracy at lower temperatures

- require less signal conditioning circuits (amplifiers, level translators, etc.)

- typically cost less

- have comparable precision;

BUT

- thermocouples can withstand very high temperatures (in the order of 600°C) and therefore used in applications at higher temperatures.

Performance Characteristics of NTC Thermistors

Unlike RTDs (Resistance Temperature Detectors), which are made from metals, NTC thermistors are generally made of ceramics or polymers. The different materials used in manufacture produce different temperature responses, as well as other characteristics. Such differences guide your selection of instruments for your application.

Temperature Range

When selecting the right thermistor for your environment, temperature operating range is an important consideration. Most NTC thermistors are suitable for use within a temperature range between −55°C and 200°C. There are also special families of NTC thermistors that can be used at temperatures approaching absolute zero (-273.15°C), as well as those specifically designed for use above 150°C.

Self–Heating Effect

The self-heating effect takes place whenever current flows through an NTC thermistor. Since a thermistor behaves as a resistor, power is dissipated as heat. The heat generated is affected by:

- current flow

- the environment

- the temperature coefficient of the thermistor

- the thermistor’s total surface area; and so on.

This attribute means the operating current of the thermistor must be kept as low as possible to reduce any self-heating effects. If an NTC thermistor passes operating currents which are too high, the heat generated can quickly dissipate and could cause false results. On the other hand, this characteristic makes NTV thermistors ideal for some niche applications, such as liquid presence detectors, often found in storage tanks.

Heat Capacity

Heat capacity means the amount of heat required to increase the temperature of the thermistor by 1°C. This is usually expressed in mJ/°C. Knowing the precise heat capacity of NTC thermistors is of great importance. For example, it’s critical if you’re looking for a sensor to function as an inrush-current limiting device. By connecting an NTC thermistor in series with a load, it is possible to effectively limit high inrush currents.

Ideal Applications for NTC Thermistors

NTC Thermistors are suitable for a wide range of applications in industries such as automotive, military, industrial, and emissions control. What’s more, many items in a home contain NTC thermistors including ovens, air conditioners, and fire detectors.

- Specific tasks suitable for NTC thermistors include:

- Measuring temperature

- Controlling temperature (e.g. a thermostat)

- Temperature compensation

- Detecting the absence or presence of a liquid

- Current limiting devices in power supply circuits

- Temperature monitoring in automotive applications and many more.

- NTC sensors can be divided into three groups, depending on the electrical characteristic you wish to exploit for an application.

Resistance-temperature characteristic

- Applications based on the resistance-time characteristic include temperature:

- measurement

- control; and

- compensation.

NTC thermistors are excellent for situations in which an NTC thermistor is used so that the temperature of the NTC temperature sensor is correlated to some other physical phenomena. This group of applications requires that the thermistor operates in a zero-power condition. Keeping the current through thermistor to a minimum will avoid heating the probe.

Current-time characteristic

- Some applications based on current-time characteristic include:

- time delay,

- inrush current limiting,

- surge suppression; and many more.

These characteristics are related to the heat capacity and the dissipation constant of the NTC thermistor used. Current passing through a circuit is calculated to heat the NTC thermistor and trigger some sort of change in the behaviour of the circuit, as required for the application you have in mind.

Voltage-current characteristic

- Applications based on the voltage-current characteristic of a thermistor generally involve changes in the environmental conditions or circuit variations. which result in changes in the operating voltage point. Depending on the application, this can be exploited for:

- current limiting,

- temperature compensation; and

- temperature measurements.

Alternative Designs of NTC Thermistors

Materials used in the fabrication of NTC resistors include platinum, nickel, cobalt, iron and oxides of silicon. These inputs are used as pure elements or combined in ceramics and polymers. Taking these materials and manufacturing technique into account allows us to classify NTC thermistors into three groups:

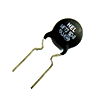

Bead Thermistors

These NTC thermistors are made from platinum alloy lead wires directly sintered into the ceramic body. On the upside, compared to Disk and Chip NTC sensors, Bead NTC thermistors offer:

These NTC thermistors are made from platinum alloy lead wires directly sintered into the ceramic body. On the upside, compared to Disk and Chip NTC sensors, Bead NTC thermistors offer:

- faster response times

- better stability; and

- allow operation at higher temperatures.

On the other hand, Bead NTC thermistors are more fragile. It is common to seal them in glass, to protect them from mechanical damage during assembly, and to improve their measurement stability. The typical sizes range from 0.075 – 5mm in diameter.

Disk and Chip Thermistors

This group of NTC thermistors are designed with metallized surface contacts. The characteristic disk shape is constructed by pressing a blend of oxide powders into a round die, which are then sintered at high temperatures. Chips are usually fabricated by a tape-casting process where a slurry of material is spread out as a thick film, dried and cut into shape. The typical sizes range from 0.25-25mm in diameter. The major negative is slower reaction times compared to bead-type NTC resistors. The positives include:

- a higher dissipation constant (power required to raise their temperature by 1°C); and

- since power dissipated by the thermistor is proportional to the square of the current, they can handle higher currents much better than bead-type thermistors.

Glass Encapsulated NTC Thermistors

In this design, each NTC temperature sensors is sealed in an airtight glass bubble. They are designed specifically for applications above 150°C, or for printed circuit board mounting, where durability is required. The glass seal improves the stability of the sensor and protects it from the environment. In manufacture bead-type NTC resistors are hermetically sealed in a glass container. Typical sizes range from 0.4-10mm in diameter.

Examples of Products Incorporating NTC Thermistors

1m 10K NTC thermistor type probe - IC-NTC-PROBE-1900

Product Code: IC-NTC-PROBE-1900. The NTC-PROBE-1900 is a 1m 10K NTC thermistor type probe with a range of -40 to +200ºC (-40 to +392ºF). This probe can be used as an external probe with the EMT 1900 temperature display.

Food probe, stainless steel (IP67) - IC-0613 3311

Product Code: IC-0613 3311 The stainless-steel food probe (NTC) is most commonly used for measuring the core temperature of foods. In this example, the probe is EN 13485 and HACCP-compliant, heat-resistant and water-protected (according to IP 67), making it particularly suitable for use in the food sector.

Product Code: IC-0613 3311 The stainless-steel food probe (NTC) is most commonly used for measuring the core temperature of foods. In this example, the probe is EN 13485 and HACCP-compliant, heat-resistant and water-protected (according to IP 67), making it particularly suitable for use in the food sector.

Core Thermometer with Thin NTC Probe and Topsafe - 0563-1063

Product Code: 0563-1063: Another style of food probe is the Testo 106 food thermometer.

Product Code: 0563-1063: Another style of food probe is the Testo 106 food thermometer.

Datalogger with an NTC Thermistor Connection

Temp. Logger with Internal Sensor & External Connection (NTC)

Temp. Logger with Internal Sensor & External Connection (NTC)

Product Code: 0572-1752. The Testo 175 T2 datalogger has an external sensor input (NTC), which enables it to be used with permitted food probes that deploy NTC thermistors. Common applications include measuring the core temperature of the goods, or the temperature between the packaging of deep-frozen goods.

If you have any questions at all regarding thermistors, if you can’t find the instrument you’re looking for, or you need advice with an application, setting up your equipment, or designing an experiment contact an Instrument Choice scientist.

Also interesting

A sensor is a device that detects and responds to a relevant input from the physical environment. Sensors can be tuned to any number of environmental parameters.

A sensor is a device that detects and responds to a relevant input from the physical environment. Sensors can be tuned to any number of environmental parameters.